Bewise Inc. www.tool-tool.com Reference source from the internet.

- This article deals with the concept of a differential in mechanics. For other meanings of "differential" see differential.

In an automobile and other wheeled vehicles, a differential is a device, usually consisting of gears, that allows each of the driving wheels to rotate at different speeds, while supplying equal torque to each of them. In automotive applications it is sometimes referred to as a "pumpkin".

[edit] Purpose

A vehicle's wheels rotate at different speeds, especially when turning corners. The differential is designed to drive a pair of wheels with equal force, while allowing them to rotate at different speeds. In vehicles without a differential, such as karts, both driving wheels are forced to rotate at the same speed, usually on a common axle driven by a simple chain-drive mechanism. When cornering, the inner wheel travels a shorter distance than the outer wheel, resulting in the inner wheel spinning and/or the outer wheel dragging. This results in difficult and unpredictable handling, damage to tires and roads and strain on, and possible failure of the entire drive train.

[edit] History

There are many claims to the invention of the differential gear, but it is likely that it was known, at least in some places, in ancient times. Here are some of the milestones in the history of this device.

- 1050 BC-771 BC: The Book of Song claimed the South Pointing Chariot, which uses a differential gear, was invented during the Western Zhou Dynasty.

- 150 BC - 100 BC - The Antikythera mechanism, discovered on an ancient shipwreck near the Greek island of Antikythera, employed a differential gear.

- 227 - 239 AD - Despite doubts from fellow ministers at court, Ma Jun from the Kingdom of Wei in China invents the first historically verifiable South Pointing Chariot, which provided cardinal direction as a non-magnetic, mechanized compass.

- 658, 666 AD - two Chinese Buddhist monks and engineers create South Pointing Chariots for Emperor Tenji of Japan.

- 1027, 1107 AD - Documented Chinese reproductions of the South Pointing Chariot by Yan Su and then Wu Deren, which described in detail the mechanical functions and gear ratios of the device much more so than earlier Chinese records.

- 1720 - Joseph Williamson uses a differential gear in a clock.

- 1810 - Rudolph Ackermann of Germany invents a four-wheel steering system for carriages, which some later writers mistakenly report as a differential.

- 1827 - modern automotive differential patented by watchmaker Onésiphore Pecqueur (1792-1852) of the Conservatoire des Arts et Métiers in France for use on a steam car. Sources: Britannica Online and [1]

- 1832 - Richard Roberts of England patents 'gear of compensation', a differential for road locomotives.

- 1876 - James Starley of Coventry invents chain-drive differential for use on bicycles; invention later used on automobiles by Karl Benz.

- 1897 - first use of differential on an Australian steam car by David Shearer.

- 1913 - Packard introduces the spiral-gear differential, which cuts gear noise.

- 1926 - Packard introduces the hypoid differential, which enables the propeller shaft and its hump in the interior of the car to be lowered.

[edit] Functional description

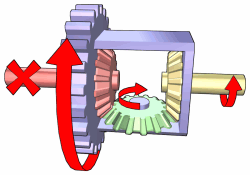

The following description of a differential applies to a "traditional" rear-wheel-drive car or truck: Power is supplied from the engine, via the gearbox, to a driveshaft (British term: propeller shaft), which runs to the rear axle. A pinion gear at the end of the propeller shaft is encased within the differential itself, and it engages with the large ring gear (British term: crownwheel), shown in the diagrams. The ring gear is attached to a carrier, which holds a set of small planetary gears. The three planetary gears are set up in such a way that the two outer gears (the side gears) can rotate in opposite directions relative to each other. The pair of side gears drive the axle shafts to each of the wheels. The entire carrier rotates in the same direction as the ring gear, but within that motion, the side gears can counter-rotate relative to each other.

Thus, for example, if the car is making a turn to the right, the main ring gear may make 10 full revolutions, and during that time, the left wheel will speed up because it has further to travel, and the right wheel will slow down correspondingly, as it has less distance to travel. The side gears will turn in opposite directions relative to each other by, say, 2 full turns each (4 full turns with regard to each other), resulting in the left wheel making 12 revolutions, and the right wheel making 8 revolutions.

When the vehicle is travelling in a straight line, there will be no movement of the planetary system of gears other than the minute movements necessary to compensate for slight differences in wheel diameter, undulations in the road (which make for a longer or shorter wheel path), etc.

[edit] Loss of traction

One undesirable side effect of a differential is that it can reduce overall torque - the rotational force which propels the vehicle. The amount of torque required to propel the vehicle at any given moment depends on the load at that instant - how heavy the vehicle is, how much drag and friction there is, the gradient of the road, the vehicle's momentum and so on. For the purpose of this article, we will refer to this amount of torque as the "threshold torque".

The torque on each wheel is a result of the engine and transmission applying torsion, a twisting force, against the resistance of the traction at that wheel. Unless the load is exceptionally high, the engine and transmission can usually supply as much torque as necessary, so the limiting factor is usually the traction under each wheel. It is therefore convenient to define traction as the amount of torque that can be generated between the tire and the ground before the wheel starts to slip. If the total traction under all the driven wheels exceeds the threshold torque, the vehicle will be driven forward; if not, then one or more wheels will simply spin.

To illustrate how a differential can limit overall torque, imagine a simple rear-wheel-drive vehicle, with one rear wheel on asphalt with good grip, and the other on a patch of slippery ice. With the load, gradient, etc., the vehicle requires, say, 2000 Nm of torque to move forward (i.e. the threshold torque). Let us further assume that the non-spinning traction on the ice equates to 400 Nm, and the asphalt to 3000 Nm.

If the two wheels were driven without a differential, each wheel would push against the ground as hard as possible. The wheel on ice would quickly reach the limit of traction (400 Nm), but would be unable to spin because the other wheel has good traction. The traction of the asphalt plus the small extra traction from the ice exceeds the threshold requirement, so the vehicle will be propelled forward.

With a differential, however, as soon as the "ice wheel" reaches 400 Nm, it will start to spin, and then develop less traction~300Nm. The planetary gears inside the differential carrier will start to rotate because the "asphalt wheel" encounters greater resistance. Instead of driving the asphalt wheel with more force, the differential will allow the ice wheel to spin faster, and the asphalt wheel to remain stationary, compensating for extra speed of the spinning ice wheel. The torque on both wheels will be the same - limited to the lesser traction of 300 Nm each. Since 600 Nm is less than the required threshold of 2000 Nm, the vehicle will not be able to move.

Note that an observer will simply see one stationary wheel and one spinning wheel. It will not be obvious that both wheels are generating the same torque (i.e. both wheels are in fact pushing equally, despite the difference in rotational speed). This has led to a widely held misconception that a vehicle with a differential is really only "one-wheel-drive". In fact, a normal differential always provides equal torque to both driven wheels (unless it is a locking, torque-biasing, or limited slip type).

[edit] Traction-adding devices

There are various devices for getting more traction from vehicles with differentials.

- One solution is the limited slip differential (LSD), the most well-known of which is the clutch-type LSD. With this differential, the side gears are coupled to the carrier via a stack of clutch plates which limits the speed difference between the two wheels.

- A locking differential employs a mechanism for allowing the planetary gears to be locked relative to each other, causing both wheels to turn at the same speed regardless of which has more traction; this is equivalent to removing the differential entirely.

- The torsen differential keeps sending some torque to the wheel with more resistance

- Electronic traction control systems usually use the ABS system to detect a spinning wheel and apply the brake to it. This progressively raises the reaction torque at that wheel, and the differential compensates by transmitting more torque through the other wheel - the one with better traction.

- A viscous coupling unit replaces the differential entirely. It works on the principle of allowing the two output shafts to counter-rotate relative to each other within a viscous fluid. The fluid allows slow relative movements of the shafts, such as those caused by cornering, but will strongly resist high-speed movements, such as those caused by a single wheel spinning.

A four-wheel-drive vehicle will have at least two differentials (one for each pair of wheels) and possibly a center differential to apportion power between the front and rear axles. Vehicles without a center differential should not be driven on dry, paved roads in four wheel drive mode, as small differences in rotational speed between the front and rear wheels cause a torque to be applied across the transmission. This phenomenon is known as "wind-up" and can cause damage to the transmission. On loose surfaces these differences are absorbed by the slippage on the road surface.

The NP242 is an example of a transfer case that acts as a center differential allowing the drive shafts to spin at different speeds. This permits the four-wheel-drive vehicle to drive on paved surfaces without experiencing "wind-up".

[edit] Non-automotive applications

A differential gear train can also be used to give the difference between two input axles. Mills often used such gears to apply torque in the required axis.

The oldest known example of a differential was once thought to be in the Antikythera mechanism. It was supposed to have used such a train to produce the difference between two inputs, one input related to the position of the sun on the zodiac, and the other input related to the position of the moon on the zodiac; the output of the differential gave a quantity related to the moon's phase. It has now been proven that the assumption of the existence of a differential gearing arrangement was incorrect.[1]

In the first half of the twentieth century, mechanical analog computers, called differential analyzers, were constructed that used differential gear trains to perform addition and subtraction.

[edit] Active differentials

A relatively new technology is the electronically-controlled active differential. A computer uses inputs from multiple sensors, including yaw rate, steering angle, and lateral acceleration and adjusts the distribution of torque to compensate for undesirable handling behaviors like understeer. Active differentials used to play a large role in the World Rally Championship, but in the 2006 season the FIA has limited the use of active differentials only to those drivers who have not competed in the World Rally Championship in the last five years.

Fully integrated active differentials are used on the Ferrari F430 and on the rear wheels in the Acura RL.

The second constraint of the differential is passive – it is actuated by the friction kinematics chain through the ground. The difference in torque on the tires (caused by turns or bumpy ground) drives the second degree of freedom, (overcoming the torque of inner friction) to equalise the driving torque on the tires. The sensitivity of the differential depends on the inner friction through the second degree of freedom. All of the differentials (so called “active” and “passive”) use clutches and brakes for restricting the second degree of freedom, so all suffer from the same disadvantage – decreased sensitivity to a dynamically changing environment. The sensitivity of the computer controlled differential is also limited by the time delay caused by sensors and the response time of the actuators.

歡迎來到Bewise Inc.的世界,首先恭喜您來到這接受新的資訊讓產業更有競爭力,我們是提供專業刀具製造商,應對客戶高品質的刀具需求,我們可以協助客戶滿足您對產業的不同要求,我們有能力達到非常卓越的客戶需求品質,這是現有相關技術無法比擬的,我們成功的滿足了各行各業的要求,包括:精密HSS DIN切削刀具、協助客戶設計刀具流程、DIN or JIS 鎢鋼切削刀具設計、NAS986 NAS965 NAS897 NAS937orNAS907 航太切削刀具,NAS航 太刀具設計、超高硬度的切削刀具、醫療配件刀具設計、汽車業刀具設計、電子產業鑽石刀具、木工產業鑽石刀具等等。我們的產品涵蓋了從民生刀具到工業級的刀 具設計;從微細刀具到大型刀具;從小型生產到大型量產;全自動整合;我們的技術可提供您連續生產的效能,我們整體的服務及卓越的技術,恭迎您親自體驗!!

BW Bewise Inc. Willy Chen willy@tool-tool.com bw@tool-tool.com www.tool-tool.com skype:willy_chen_bw mobile:0937-618-190 Head &Administration Office No.13,Shiang Shang 2nd St., West Chiu Taichung,Taiwan 40356 TEL:+886 4 24710048 / FAX:+886 4 2471 4839 N.Branch

Welcome to BW tool world! We are an experienced tool maker specialized in cutting tools. We focus on what you need and endeavor to research the best cutter to satisfy users’ demand. Our customers involve wide range of industries, like mold & die, aerospace, electronic, machinery, etc. We are professional expert in cutting field. We would like to solve every problem from you. Please feel free to contact us, its our pleasure to serve for you. BW product including: cutting tool、aerospace tool .HSS DIN Cutting tool、Carbide end mills、Carbide cutting tool、NAS Cutting tool、NAS986 NAS965 NAS897 NAS937orNAS907 Cutting Tools,Carbide end mill、disc milling cutter,Aerospace cutting tool、Фрезеры’Carbide drill、High speed steel、Milling cutter、CVDD(Chemical Vapor Deposition Diamond )’PCBN (Polycrystalline Cubic Boron Nitride) ’Core drill、Tapered end mills、CVD Diamond Tools Inserts’PCD Edge-Beveling Cutter(Golden Finger’PCD V-Cutter’PCD Wood tools’PCD Cutting tools’PCD Circular Saw Blade’PVDD End Mills’diamond tool ‘Single Crystal Diamond ‘Metric end mills、Miniature end mills、Специальные режущие инструменты ‘Пустотелое сверло ‘Pilot reamer、Fraises’Fresas con mango’ PCD (Polycrystalline diamond) ‘Frese’Electronics cutter、Step drill、Metal cutting saw、Double margin drill、Gun barrel、Angle milling cutter、Carbide burrs、Carbide tipped cutter、Chamfering tool、IC card engraving cutter、Side cutter、NAS tool、DIN or JIS tool、Special tool、Metal slitting saws、Shell end mills、Side and face milling cutters、Side chip clearance saws、Long end mills、Stub roughing end mills、Dovetail milling cutters、Carbide slot drills、Carbide torus cutters、Angel carbide end mills、Carbide torus cutters、Carbide ball-nosed slot drills、Mould cutter、Tool manufacturer.

Bewise Inc. www.tool-tool.com

ようこそBewise Inc.の世界へお越し下さいませ、先ず御目出度たいのは新たな

情報を受け取って頂き、もっと各産業に競争力プラス展開。

弊社は専門なエンド・ミルの製造メーカーで、客先に色んな分野のニーズ、

豊富なパリエーションを満足させ、特にハイテク品質要求にサポート致します。

弊社は各領域に供給できる内容は:

(1)精密HSSエンド・ミルのR&D

(2)Carbide Cutting tools設計

(3)鎢鋼エンド・ミル設計

(4)航空エンド・ミル設計

(5)超高硬度エンド・ミル

(6)ダイヤモンド・エンド・ミル

(7)医療用品エンド・ミル設計

(8)自動車部品&材料加工向けエンド・ミル設計

弊社の製品の供給調達機能は:

(1)生活産業~ハイテク工業までのエンド・ミル設計

(2)ミクロ・エンド・ミル~大型エンド・ミル供給

(3)小Lot生産~大量発注対応供給

(4)オートメーション整備調達

(5)スポット対応~流れ生産対応

弊社の全般供給体制及び技術自慢の総合専門製造メーカーに貴方のご体験を御待ちしております。

BW специализируется в научных исследованиях и разработках, и снабжаем самым высокотехнологичным карбидовым материалом для поставки режущих / фрезеровочных инструментов для почвы, воздушного пространства и электронной индустрии. В нашу основную продукцию входит твердый карбид / быстрорежущая сталь, а также двигатели, микроэлектрические дрели, IC картонорезальные машины, фрезы для гравирования, режущие пилы, фрезеры-расширители, фрезеры-расширители с резцом, дрели, резаки форм для шлицевого вала / звездочки роликовой цепи, и специальные нано инструменты. Пожалуйста, посетите сайт www.tool-tool.com для получения большей информации.

No comments:

Post a Comment