An engineering drawing is a type of drawing that is technical in nature, used to fully and clearly define requirements for engineered items, and is usually created in accordance with standardized conventions for layout, nomenclature, interpretation, appearance (such as typefaces and line styles), size, etc. Its purpose is to accurately and unambiguously capture all the geometric features of a product or a component. The end goal of an engineering drawing is to convey all the required information that will allow a manufacturer to produce that component.

Engineering drawings are often referred to as "blueprints" or "bluelines". However, the terms are rapidly becoming an anachronism, since most copies of engineering drawings that were formerly made using a chemical-printing process that yielded graphics on blue-colored paper or, alternatively, of blue-lines on white paper, have been superseded by more modern reproduction processes that yield black or multicolour lines on white paper.

The process of producing engineering drawings, and the skill of producing them, is often referred to as technical drawing, although technical drawings are also required for disciplines that would not ordinarily be thought of as parts of engineering.

[edit] Common features of engineering drawings

Drawings convey the following critical information:

- Geometry – the shape of the object; represented as views; how the object will look when it is viewed from various standard directions, such as front, top, side, etc.

- Dimensions – the size of the object is captured in accepted units.

- Tolerances – the allowable variations for each dimension.

- Material – represents what the item is made of.

- Finish – specifies the surface quality of the item, functional or cosmetic. For example, a mass-marketed product usually requires a much higher surface quality than, say, a component that goes inside industrial machinery.

[edit] Line styles and types

A variety of line styles graphically represent physical objects. Types of lines include the following:

- visible – are continuous lines used to depict edges directly visible from a particular angle.

- hidden – are short-dashed lines that may be used to represent edges that are not directly visible.

- center – are alternately long- and short-dashed lines that may be used to represent the axes of circular features.

- cutting plane – are thin, medium-dashed lines, or thick alternately long- and double short-dashed that may be used to define sections for section views.

- section – are thin lines in a pattern (pattern determined by the material being "cut" or "sectioned") used to indicate surfaces in section views resulting from "cutting." Section lines are commonly referred to as "cross-hatching."

Lines can also be classified by a letter classification in which each line is given a letter.

- Type A lines show the outline of the feature of an object. They are the thickest lines on a drawing and done with a pencil softer than HB.

- Type B lines are dimension lines and are used for dimensioning, projecting, extending, or leaders. A harder pencil should be used, such as a 2H.

- Type C lines are used for breaks when the whole object is not shown. They are freehand drawn and only for short breaks. 2H pencil

- Type D lines are similar to Type C, except they are zigzagged and only for longer breaks. 2H pencil

- Type E lines indicate hidden outlines of internal features of an object. They are dotted lines. 2H pencil

- Type F lines are Type F[typo] lines, except they are used for drawings in electrotechnology. 2H pencil

- Type G lines are used for centre lines. They are dotted lines, but a long line of 10–20mm, then a gap, then a small line of 2mm. 2H pencil

- Type H lines are the same as Type G, except that every second long line is thicker. They indicate the cutting plane of an object. 2H pencil

- Type K lines indicate the alternate positions of an object and the line taken by that object. They are drawn with a long line of 10–20mm, then a small gap, then a small line of 2mm, then a gap, then another small line. 2H pencil.

[edit] Example of an engineering drawing

Here is an example of an engineering drawing. The different line types are colored for clarity.

Black = object line and hatching

Red = hidden line

Blue = center line

Magenta = phantom line or cutting plane

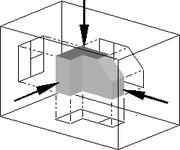

Sectional views are indicated by the direction of arrows, as in the example above.

[edit] Multiple views and projections

In most cases, a single view is not sufficient to show all necessary features, and several views are used. Types of views include the following:

[edit] Orthographic projection

"Orthographic" comes from the Greek word for "straight writing (or drawing)." This projection shows the object as it looks from the front, right, left, top, bottom, or back, and are typically positioned relative to each other according to the rules of either first-angle or third-angle projection.

- First angle projection is the ISO standard and is primarily used in Europe and Asia. The 3D object is projected into 2D "paper" space as if you were looking at an X-ray of the object: the top view is under the front view, the right view is at the left of the front view.

- Third angle projection is primarily used in the United States and Canada, places the left view on the left and the top view on the top.

Not all views are necessarily used, and determination of what surface constitutes the front, back, top and bottom varies depending on the projection used.

[edit] Section

Depict what the object would look like if it were cut perfectly along cutting plane lines defined in a particular view, and rotated 90° to directly view the resulting surface(s), which are indicated with section lines. They show features not externally visible, or not clearly visible.

[edit] Detail

Show portions of other views, "magnified" for clarity.

[edit] Auxiliary projection

Similar to orthographic projections, however the directions

[edit] Isometric projection

Show the object from angles in which the scales along each axis of the object are equal. It corresponds to rotation of the object by ± 45° about the vertical axis, followed by rotation of approximately ± 35.264° [= arcsin(tan(30°))] about the horizontal axis starting from an orthographic projection view. "Isometric" comes from the Greek for "same measure." One of the things that makes isometric drawings so attractive is the ease with which 60 degree angles can be constructed with only a compass and straightedge.

[edit] Showing dimensions

The required sizes of features are conveyed through use of dimensions. Distances may be indicated with either of two standardized forms of dimension: linear and ordinate.

- With linear dimensions, two parallel lines, called "extension lines," spaced at the distance between two features, are shown at each of the features. A line perpendicular to the extension lines, called a "dimension line," with arrows at its endpoints, is shown between, and terminating at, the extension lines. The distance is indicated numerically at the midpoint of the dimension line, either adjacent to it, or in a gap provided for it.

- With ordinate dimensions, one horizontal and one vertical extension line establish an origin for the entire view. The origin is identified with zeroes placed at the ends of these extension lines. Distances along the x- and y-axes to other features are specified using other extension lines, with the distances indicated numerically at their ends.

Sizes of circular features are indicated using either diametral or radial dimensions. Radial dimensions use an "R" followed by the value for the radius; Diametral dimensions use a circle with forward-leaning diagonal line through it, called the diameter symbol, followed by the value for the diameter. A radially-aligned line with arrowhead pointing to the circular feature, called a leader, is used in conjunction with both diametral and radial dimensions. All types of dimensions are typically composed of two parts: the nominal value, which is the "ideal" size of the feature, and the tolerance, which specifies the amount that the value may vary above and below the nominal.

- Geometric Dimensioning and Tolerancing is a method of specifying the functional geometry of an object.

[edit] Sizes of drawings

Sizes of drawings typically comply with either of two different standards, ISO (World Standard) or U.S. customary, according to the following tables:

| A4 | 210 X 297 |

|---|---|

| A3 | 297 X 420 |

| A2 | 420 X 594 |

| A1 | 594 X 841 |

| A0 | 841 X 1189 |

| A | 8.5" X 11" |

|---|---|

| B | 11" X 17" |

| C | 17" X 22" |

| D | 22" X 34" |

| E | 34" X 44" |

| D1 | 24" X 36" |

|---|---|

| E1 | 30" X 42" |

The metric drawing sizes correspond to international paper sizes. These developed further refinements in the second half of the twentieth century, when photocopying became cheap. Engineering drawings could be readily doubled (or halved) in size and put on the next larger (or, respectively, smaller) size of paper with no waste of space. And the metric technical pens were chosen in sizes so that one could add detail or drafting changes with a pen of double (or half) the width to the copy.

The U.S. customary "A-size" corresponds to "letter" size, and "B-size" corresponds to "ledger" or "tabloid" size. There were also once British paper sizes, which went by names rather than alphanumeric designations.

ANSI Y14.2, Y14.3, and Y14.5 are standards that are commonly used in the U.S.

歡迎來到Bewise Inc.的世界,首先恭喜您來到這接受新的資訊讓產業更有競爭力,我們是提供專業刀具製造商,應對客戶高品質的刀具需求,我們可以協助客戶滿足您對產業的不同要求,我們有能力達到非常卓越的客戶需求品質,這是現有相關技術無法比擬的,我們成功的滿足了各行各業的要求,包括:精密HSS DIN切削刀具、協助客戶設計刀具流程、DIN or JIS 鎢鋼切削刀具設計、NAS986 NAS965 NAS897 NAS937orNAS907 航太切削刀具,NAS航太刀具設計、超高硬度的切削刀具、BW捨棄式鑽石V卡刀’BW捨棄式金屬圓鋸片、木工捨棄式金屬圓鋸片、PCD木工圓鋸片、醫療配件刀具設計、汽車業刀具設計、電子產業鑽石刀具、全鎢鋼V卡刀-電路版專用’全鎢鋼鋸片、焊刃式側銑刀、焊刃式千鳥側銑刀、焊刃式T型銑刀、焊刃式千鳥T型銑刀、焊刃式螺旋機械鉸刀、全鎢鋼斜邊刀電路版專用、鎢鋼焊刃式高速鉸刀、超微粒鎢鋼機械鉸刀、超微粒鎢鋼定點鑽、焊刃式帶柄角度銑刀、焊刃式螺旋立銑刀、焊刃式帶柄倒角銑刀、焊刃式角度銑刀、焊刃式筒型平面銑刀、木工產業鑽石刀具等等。我們的產品涵蓋了從民生刀具到工業級的刀具設計;從微細刀具到大型刀具;從小型生產到大型量產;全自動整合;我們的技術可提供您連續生產的效能,我們整體的服務及卓越的技術,恭迎您親自體驗!!

BW Bewise Inc. Willy Chen willy@tool-tool.com bw@tool-tool.com www.tool-tool.com skype:willy_chen_bw mobile:0937-618-190 Head &Administration Office No.13,Shiang Shang 2nd St., West Chiu Taichung,Taiwan 40356 http://www.tool-tool..com / FAX:+886 4 2471 4839 N.Branch 5F,No.460,Fu Shin North Rd.,Taipei,Taiwan S.Branch No.24,Sec.1,Chia Pu East Rd.,Taipao City,Chiayi Hsien,Taiwan

Welcome to BW tool world! We are an experienced tool maker specialized in cutting tools. We focus on what you need and endeavor to research the best cutter to satisfy users’ demand. Our customers involve wide range of industries, like mold & die, aerospace, electronic, machinery, etc. We are professional expert in cutting field. We would like to solve every problem from you. Please feel free to contact us, its our pleasure to serve for you. BW product including: cutting tool、aerospace tool .HSS DIN Cutting tool、Carbide end mills、Carbide cutting tool、NAS Cutting tool、NAS986 NAS965 NAS897 NAS937orNAS907 Cutting Tools,Carbide end mill、disc milling cutter,Aerospace cutting tool、hss drill’Фрезеры’Carbide drill、High speed steel、Milling cutter、CVDD(Chemical Vapor Deposition Diamond )’PCBN (Polycrystalline Cubic Boron Nitride) ’Core drill、Tapered end mills、CVD Diamond Tools Inserts’PCD Edge-Beveling Cutter(Golden Finger’Edge modifying knife’Solid carbide saw blade-V type’V-type locking-special use for PC board’Metal Slitting Sawa’Carbide Side milling Cutters’Carbide Side Milling Cutters With Staggered Teeth’Carbide T-Slot Milling Cutters’Carbide T-Slot Milling Cutters With Staggered Teeth’Carbide Machine Reamers’High speed reamer-standard type’High speed reamer-long type’’PCD V-Cutter’PCD Wood tools’PCD Cutting tools’PCD Circular Saw Blade’PVDD End Mills’diamond tool ‘V-type locking-special use for PC board ‘Single Crystal Diamond ‘Metric end mills、Miniature end mills、Специальные режущие инструменты ‘Пустотелое сверло ‘Pilot reamer、Fraises’Fresas con mango’ PCD (Polycrystalline diamond) ‘Frese’Electronics cutter、Step drill、Metal cutting saw、Double margin drill、Gun barrel、Angle milling cutter、Carbide burrs、Carbide tipped cutter、Chamfering tool、IC card engraving cutter、Side cutter、NAS tool、DIN or JIS tool、Special tool、Metal slitting saws、Shell end mills、Side and face milling cutters、Side chip clearance saws、Long end mills、Stub roughing end mills、Dovetail milling cutters、Carbide slot drills、Carbide torus cutters、Angel carbide end mills、Carbide torus cutters、Carbide ball-nosed slot drills、Mould cutter、Tool manufacturer.

ようこそBewise Inc.の世界へお越し下さいませ、先ず御目出度たいのは新たな

情報を受け取って頂き、もっと各産業に競争力プラス展開。

弊社は専門なエンド・ミルの製造メーカーで、客先に色んな分野のニーズ、

豊富なパリエーションを満足させ、特にハイテク品質要求にサポート致します。

弊社は各領域に供給できる内容は:

(3)鎢鋼エンド・ミル設計

(4)航空エンド・ミル設計

(5)超高硬度エンド・ミル

(7)医療用品エンド・ミル設計

弊社の製品の供給調達機能は:

(4)オートメーション整備調達

弊社の全般供給体制及び技術自慢の総合専門製造メーカーに貴方のご体験を御待ちしております。

BW специализируется в научных исследованиях и разработках, и снабжаем самым высокотехнологичным карбидовым материалом для поставки режущих / фрезеровочных инструментов для почвы, воздушного пространства и электронной индустрии. В нашу основную продукцию входит твердый карбид / быстрорежущая сталь, а также двигатели, микроэлектрические дрели, IC картонорезальные машины, фрезы для гравирования, режущие пилы, фрезеры-расширители, фрезеры-расширители с резцом, дрели, резаки форм для шлицевого вала / звездочки роликовой цепи, и специальные нано инструменты. Пожалуйста, посетите сайт www.tool-tool.com для получения большей информации.

BW is specialized in R&D and sourcing the most advanced carbide material with high-tech coating to supply cutting / milling tool for mould & die, aero space and electronic industry. Our main products include solid carbide / HSS end mills, micro electronic drill, IC card cutter, engraving cutter, shell end mills, cutting saw, reamer, thread reamer, leading drill, involute gear cutter for spur wheel, rack and worm milling cutter, thread milling cutter, form cutters for spline shaft/roller chain sprocket, and special tool, with nano grade. Please visit our web www.tool-tool.com for more info.

No comments:

Post a Comment