Bewise Inc. www.tool-tool.com Reference source from the internet.

In signal processing, a comb filter adds a delayed version of a signal to itself, causing constructive and destructive interference. The frequency response of a comb filter consists of a series of regularly-spaced spikes, giving the appearance of a comb.

[edit] Applications

Comb filters are used in a variety of signal processing applications. These include:

- Cascaded Integrator-Comb (CIC) filters, commonly used for anti-aliasing during interpolation and decimation operations that change the sample rate of a discrete-time system.

- 2D and 3D comb filters implemented in hardware (and occasionally software) for PAL and NTSC television decoders. The filters work to reduce artifacts such as dot crawl.

- Audio effects, including echo, flanging, and digital waveguide synthesis. For instance, if the delay is set to a few milliseconds, a comb filter can be used to model the effect of acoustic standing waves in a cylindrical cavity or in a vibrating string.

[edit] Technical discussion

Comb filters exist in two different forms, feedforward and feedback; the names refer to the direction in which signals are delayed before they are added to the input.

Comb filters may be implemented in discrete time or continuous time; this article will focus on discrete-time implementations; the properties of the continuous-time comb filter are very similar.

[edit] Feedforward form

Feedforward comb filter structure

The general structure of a feedforward comb filter is shown on the right. It may be described by the following difference equation:

where K is the delay length (measured in samples), and α is a scaling factor applied to the delayed signal. If we take the Z transform of both sides of the equation, we obtain:

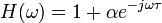

We define the transfer function as:

[edit] Frequency response

Feedforward magnitude response for various positive values of α

Feedforward magnitude response for various negative values of α

To obtain the frequency response of a discrete-time system expressed in the Z domain, we make the substitution z = ejω. Therefore, for our feedforward comb filter, we get:

Using Euler's formula, we find that the frequency response is also given by

Often of interest is the magnitude response, which ignores phase. This is defined as:

In the case of the feedforward comb filter, this is:

Notice that the (1 + α2) term is constant, whereas the 2αcos(ωK) term varies periodically. Hence the magnitude response of the comb filter is periodic.

The graphs to the right show the magnitude response for various values of α, demonstrating this periodicity. Some important properties:

- The response periodically drops to a local minimum (sometimes known as a notch), and periodically rises to a local maximum (sometimes known as a peak).

- The levels of the maxima and minima are always equidistant from 1.

- When

, the minima have zero amplitude. In this case, the minima are sometimes known as nulls.

, the minima have zero amplitude. In this case, the minima are sometimes known as nulls. - The maxima for positive values of α coincide with the minima for negative values of α, and vice versa.

[edit] Pole-zero interpretation

Looking again at the Z-domain transfer function of the feedforward comb filter:

we see that the numerator is equal to zero whenever zK = − α. This has K solutions, equally spaced around a circle in the complex plane; these are the zeros of the transfer function. The denominator is zero at zK = 0, giving K poles at z = 0. This leads to a pole-zero plot like the ones shown below.

Pole-zero plot of feedfoward comb filter with K = 8 and α = 0.5

Pole-zero plot of feedfoward comb filter with K = 8 and α = − 0.5

[edit] Feedback form

Feedback comb filter structure

Similarly, the general structure of a feedback comb filter is shown on the right. It may be described by the following difference equation:

If we rearrange this equation so that all terms in y are on the left-hand side, and then take the Z transform, we obtain:

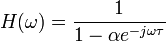

The transfer function is therefore:

[edit] Frequency response

Feedback magnitude response for various positive values of α

Feedback magnitude response for various negative values of α

If we make the substitution z = ejω into the Z-domain expression for the feedback comb filter, we get:

The magnitude response is as follows:

Again, the response is periodic, as the graphs to the right demonstrate. The feedback comb filter has some properties in common with the feedforward form:

- The response periodically drops to a local minimum and rises to a local maximum.

- The maxima for positive values of α coincide with the minima for negative values of α, and vice versa.

However, there are also some important differences because the magnitude response has a term in the denominator:

- The levels of the maxima and minima are no longer equidistant from 1.

- The filter is only stable if | α | is strictly less than 1. As can be seen from the graphs, as | α | increases, the amplitude of the maxima rises increasingly rapidly.

[edit] Pole-zero interpretation

Looking again at the Z-domain transfer function of the feedback comb filter:

This time, the numerator is zero at zK = 0, giving K zeros at z = 0. The denominator is equal to zero whenever zK = α. This has K solutions, equally spaced around a circle in the complex plane; these are the poles of the transfer function. This leads to a pole-zero plot like the ones shown below.

Pole-zero plot of feedback comb filter with K = 8 and α = 0.5

Pole-zero plot of feedback comb filter with K = 8 and α = − 0.5

[edit] Continuous-time comb filters

Comb filters may also be implemented in continuous time. The feedforward form may be described by the following equation:

and the feedback form by:

where τ is the delay (measured in seconds).

They have the following frequency responses, respectively:

Continuous-time implementations share all the properties of the respective discrete-time implementations.

歡迎來到Bewise Inc.的世界,首先恭喜您來到這接受新的資訊讓產業更有競爭力,我們是提供專業刀具製造商,應對客戶高品質的刀具需求,我們可以協助客戶滿足您對產業的不同要求,我們有能力達到非常卓越的客戶需求品質,這是現有相關技術無法比擬的,我們成功的滿足了各行各業的要求,包括:精密HSS DIN切削刀具、協助客戶設計刀具流程、DIN or JIS 鎢鋼切削刀具設計、NAS986 NAS965 NAS897 NAS937orNAS907 航太切削刀具,NAS航太刀具設計、超高硬度的切削刀具、醫療配件刀具設計、複合式再研磨機、PCD地板專用企口鑽石組合刀具、NSK高數主軸與馬達、專業模具修補工具-氣動與電動、粉末造粒成型機、主機版專用頂級電桿、PCD V-Cut刀、捨棄式圓鋸片組、粉末成型機、主機版專用頂級電感、’汽車業刀具設計、電子產業鑽石刀具、木工產業鑽石刀具、銑刀與切斷複合再研磨機、銑刀與鑽頭複合再研磨機、銑刀與螺絲攻複合再研磨機等等。我們的產品涵蓋了從民生刀具到工業級的刀具設計;從微細刀具到大型刀具;從小型生產到大型量產;全自動整合;我們的技術可提供您連續生產的效能,我們整體的服務及卓越的技術,恭迎您親自體驗!!

BW Bewise Inc. Willy Chen willy@tool-tool.com bw@tool-tool.com www.tool-tool.com skype:willy_chen_bw mobile:0937-618-190 Head &Administration Office No.13,Shiang Shang 2nd St., West Chiu Taichung,Taiwan 40356 http://www.tool-tool.com / FAX:+886 4 2471 4839 N.Branch 5F,No.460,Fu Shin North Rd.,Taipei,Taiwan S.Branch No.24,Sec.1,Chia Pu East Rd.,Taipao City,Chiayi Hsien,Taiwan

Welcome to BW tool world! We are an experienced tool maker specialized in cutting tools. We focus on what you need and endeavor to research the best cutter to satisfy users’ demand. Our customers involve wide range of industries, like mold & die, aerospace, electronic, machinery, etc. We are professional expert in cutting field. We would like to solve every problem from you. Please feel free to contact us, its our pleasure to serve for you. BW product including: cutting tool、aerospace tool .HSS DIN Cutting tool、Carbide end mills、Carbide cutting tool、NAS Cutting tool、NAS986 NAS965 NAS897 NAS937orNAS907 Cutting Tools,Carbide end mill、disc milling cutter,Aerospace cutting tool、hss drill’Фрезеры’Carbide drill、High speed steel、Compound Sharpener’Milling cutter、INDUCTORS FOR PCD’CVDD(Chemical Vapor Deposition Diamond )’PCBN (Polycrystalline Cubic Boron Nitride) ’Core drill、Tapered end mills、CVD Diamond Tools Inserts’PCD Edge-Beveling Cutter(Golden Finger’PCD V-Cutter’PCD Wood tools’PCD Cutting tools’PCD Circular Saw Blade’PVDD End Mills’diamond tool. INDUCTORS FOR PCD . POWDER FORMING MACHINE ‘Single Crystal Diamond ‘Metric end mills、Miniature end mills、Специальные режущие инструменты ‘Пустотелое сверло ‘Pilot reamer、Fraises’Fresas con mango’ PCD (Polycrystalline diamond) ‘Frese’POWDER FORMING MACHINE’Electronics cutter、Step drill、Metal cutting saw、Double margin drill、Gun barrel、Angle milling cutter、Carbide burrs、Carbide tipped cutter、Chamfering tool、IC card engraving cutter、Side cutter、Staple Cutter’PCD diamond cutter specialized in grooving floors’V-Cut PCD Circular Diamond Tipped Saw Blade with Indexable Insert’ PCD Diamond Tool’ Saw Blade with Indexable Insert’NAS tool、DIN or JIS tool、Special tool、Metal slitting saws、Shell end mills、Side and face milling cutters、Side chip clearance saws、Long end mills’end mill grinder’drill grinder’sharpener、Stub roughing end mills、Dovetail milling cutters、Carbide slot drills、Carbide torus cutters、Angel carbide end mills、Carbide torus cutters、Carbide ball-nosed slot drills、Mould cutter、Tool manufacturer.

ようこそBewise Inc.の世界へお越し下さいませ、先ず御目出度たいのは新たな

情報を受け取って頂き、もっと各産業に競争力プラス展開。

弊社は専門なエンド・ミルの製造メーカーで、客先に色んな分野のニーズ、

豊富なパリエーションを満足させ、特にハイテク品質要求にサポート致します。

弊社は各領域に供給できる内容は:

(3)鎢鋼エンド・ミル設計

(4)航空エンド・ミル設計

(5)超高硬度エンド・ミル

(7)医療用品エンド・ミル設計

弊社の製品の供給調達機能は:

(4)オートメーション整備調達

弊社の全般供給体制及び技術自慢の総合専門製造メーカーに貴方のご体験を御待ちしております。

Bewise Inc. talaşlı imalat sanayinde en fazla kullanılan ve üç eksende (x,y,z) talaş kaldırabilen freze takımlarından olan Parmak Freze imalatçısıdır. Çok geniş ürün yelpazesine sahip olan firmanın başlıca ürünlerini Karbür Parmak Frezeler, Kalıpçı Frezeleri, Kaba Talaş Frezeleri, Konik Alın Frezeler, Köşe Radyüs Frezeler, İki Ağızlı Kısa ve Uzun Küresel Frezeler, İç Bükey Frezeler vb. şeklinde sıralayabiliriz.

BW специализируется в научных исследованиях и разработках, и снабжаем самым высокотехнологичным карбидовым материалом для поставки режущих / фрезеровочных инструментов для почвы, воздушного пространства и электронной индустрии. В нашу основную продукцию входит твердый карбид / быстрорежущая сталь, а также двигатели, микроэлектрические дрели, IC картонорезальные машины, фрезы для гравирования, режущие пилы, фрезеры-расширители, фрезеры-расширители с резцом, дрели, резаки форм для шлицевого вала / звездочки роликовой цепи, и специальные нано инструменты. Пожалуйста, посетите сайт www.tool-tool.com для получения большей информации.

BW is specialized in R&D and sourcing the most advanced carbide material with high-tech coating to supply cutting / milling tool for mould & die, aero space and electronic industry. Our main products include solid carbide / HSS end mills, micro electronic drill, IC card cutter, engraving cutter, shell end mills, cutting saw, reamer, thread reamer, leading drill, involute gear cutter for spur wheel, rack and worm milling cutter, thread milling cutter, form cutters for spline shaft/roller chain sprocket, and special tool, with nano grade. Please visit our web www.tool-tool.com for more info.

![\ y[n] = x[n] + \alpha x[n-K] \,](http://upload.wikimedia.org/math/d/1/c/d1ceb58989ca1e7aa59380e4dd2bfe6f.png)

![\ H(e^{j \omega}) = \left[1 + \alpha \cos(\omega K)\right] - j \alpha \sin(\omega K) \,](http://upload.wikimedia.org/math/0/2/d/02da5b7f3b638a628a34d901dc61a479.png)

![\ y[n] = x[n] + \alpha y[n-K] \,](http://upload.wikimedia.org/math/c/d/e/cdefb4d2fae385ecaeb563040f0a6602.png)

No comments:

Post a Comment